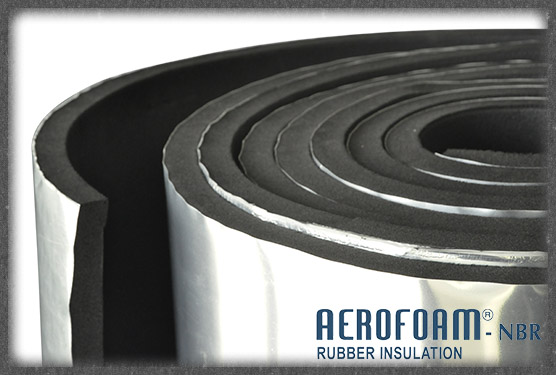

Aerofoam® NBR CLAD sheets & rolls are made from closed cell rubber foam coated with a strong jacketing, which replaces costly and complex aluminium and stainless steel sheet facings. The foam has a microcell, non porous structure and a closed cell content bigger than 90%. It has a very good dimensional stability and offers an excellent protection against condensation, thermal loss and sound transfer.

The Aerofoam® NBR CLAD rolls & sheets represent an economical solution to the expensive and labor intensive aluminum or stainless steel cladding. Some of the benefits are the following: less skilled labor required, fast installation (50% faster than aluminum cladding), light weight material (0.34 Kg/m2), safe to use (PVC jacketing – no safety equipment required), easy to cut, no drill required (light punching tool is enough), no power tools required, easy and light to lift and carry, jackets can be cut on-site without waste (on a cutting table), space-saving storage.

Material: closed cell elastomeric foam with PVC silver jacketing

Density: 60 – 70 kg/m³

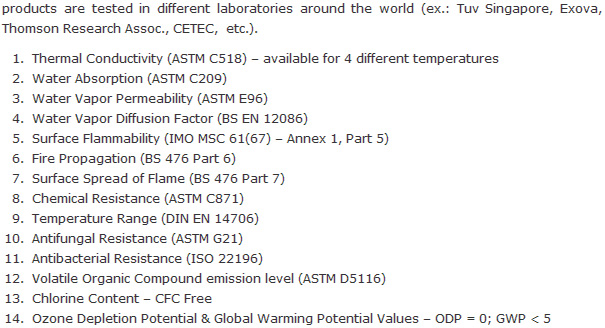

Thickness: 6 mm, 9 mm, 13 mm, 19 mm, 25 mm, 32 mm, 40 mm

Width: 1 m

Length: see table below

Color: black substrate with silver facing

- Indoor and outdoor pipe or duct applications

- Tanks, reservoirs

- UV and corrosion resistance;

- Fire rated “CLASS O” as per BS 476 Parts 6 & 7;

- Very low water vapor permeance (0 perms);

- High water vapor diffusion factor (> 7,300);

- Very low water absorption rate (0.06% by volume);

- High thermal efficiency (λ24˚ C = 0.033 W/mK; λ46˚ C = 0.035 W/mK);

- Wide temperature range (from -50˚ C to +105˚ C);

- Chemical resistance – resistant to most chemicals (sodium, silica, fluoride, chloride, etc.);

- Antibacterial & antifungal;

- Environmental friendly – ODP = 0 and GWP < 5;

- Very low VOC emission level ( < 6 µg/m2/hr in 24 hours);

- Sound absorption properties;

- Easy and fast to install.