Aerofoam® NBR Rolls & Sheets are made from closed cell rubber foam, which has a microcell, non porous structure and a closed cell content bigger than 90%. They can be coated with different types of foils and can have also a factory-applied self-adhesive backing, depending on the customers’ needs. The Aerofoam® NBR rolls & sheets have a very good dimensional stability and offer an excellent protection against condensation, thermal loss and sound transfer. The installation time is reduced more than 40% due to the cutting easiness and the quick adhesion capacity of the material.

The rolls & sheets represent no hazard to the human health, being used no CFC or HCFC in their production and having a very low VOC level. They are considered environmental friendly products (with low Ozone Depletion Potential – ODP – and Global Warming Potential – GWP) and comply with the LEED requirements, helping buildings to get more LEED points.

Material: closed cell elastomeric foam

Density: 60 – 70 kg/m³

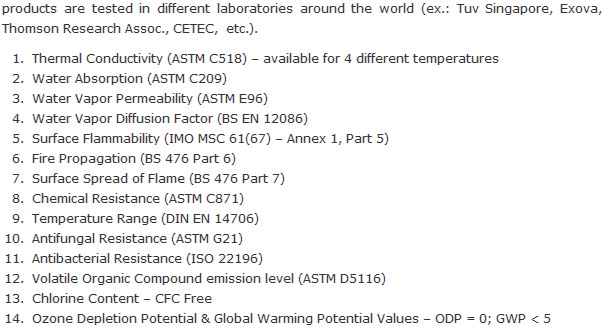

Thickness: 6 mm, 9 mm, 13 mm, 19 mm, 25 mm, 32 mm, 40 mm, 50 mm

Width: 1 m

Length: see table below

Color: black

- Big diameter pipes (where tubes can’t be used)

- Ventilation ducts

- Tanks, reservoirs

- Engine rooms (as sound attenuators)

- Fire rated “CLASS O” as per BS 476 Parts 6 & 7;

- Very low water vapor permeance (0 perms);

- High water vapor diffusion factor (> 7,300);

- Very low water absorption rate (0.06% by volume);

- High thermal efficiency (λ24˚ C = 0.033 W/mK; λ46˚ C = 0.035 W/mK);

- Wide temperature range (from -50˚ C to +105˚ C);

- Chemical resistance – resistant to most chemicals (sodium, silica, fluoride, chloride, etc.);

- Antibacterial & antifungal;

- Environmental friendly – ODP = 0 and GWP < 5;

- Very low VOC emission level ( < 6 µg/m2/hr in 24 hours);

- Sound absorption properties;

- Easy and fast to install.